Ofite is a leading provider of instrument technology and service. We have been providing complete oilfield testing equipment solutions for the last 30 years to a variety of clients worldwide.

Our experience, service and problem solving techniques have lead to us to continuously seek out better products and solutions for our clients. This is made possible by truly understanding our clients needs and being proactive in providing new technologies.

This mind set, or business model, allows our team to constantly look ahead, anticipating new ways that would give our clients better information… faster.

Sometimes this effort produces results that are truly remarkable.

This analysis used to need a laboratory environment, now it is available on site.

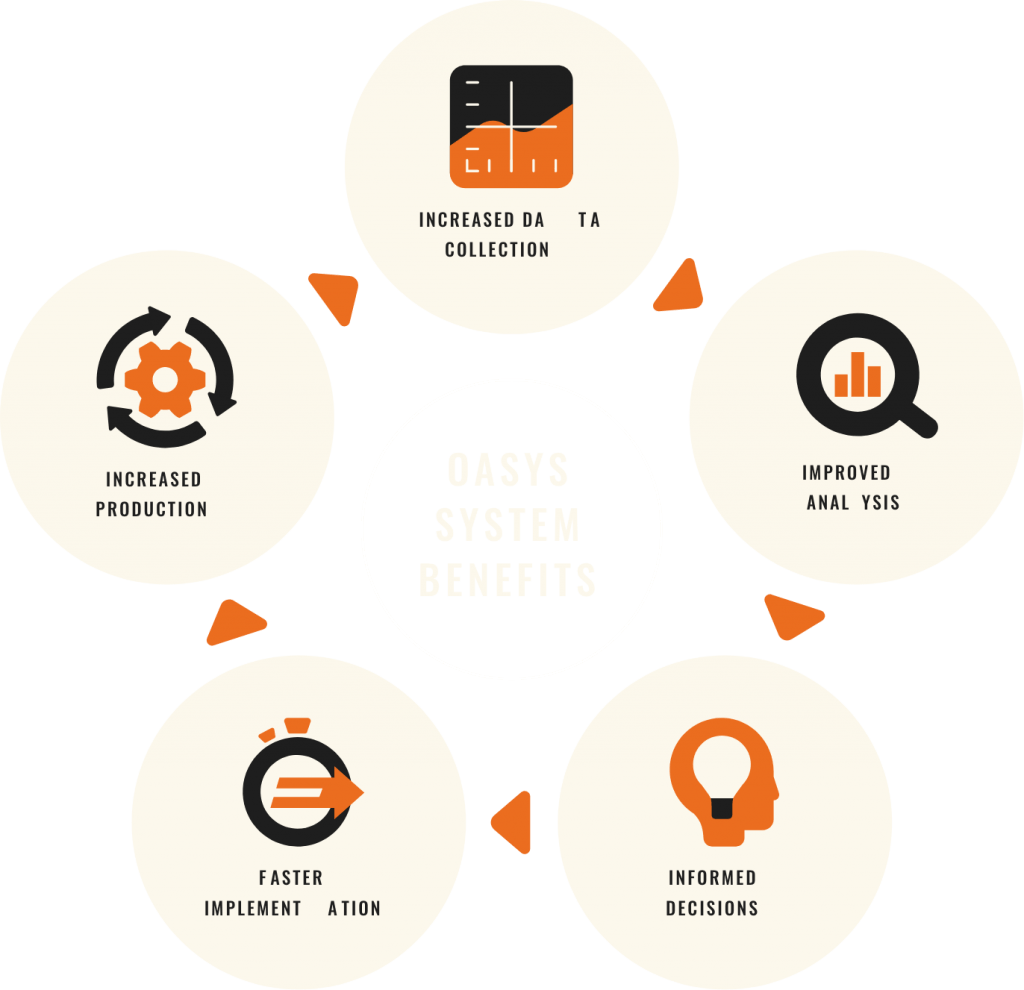

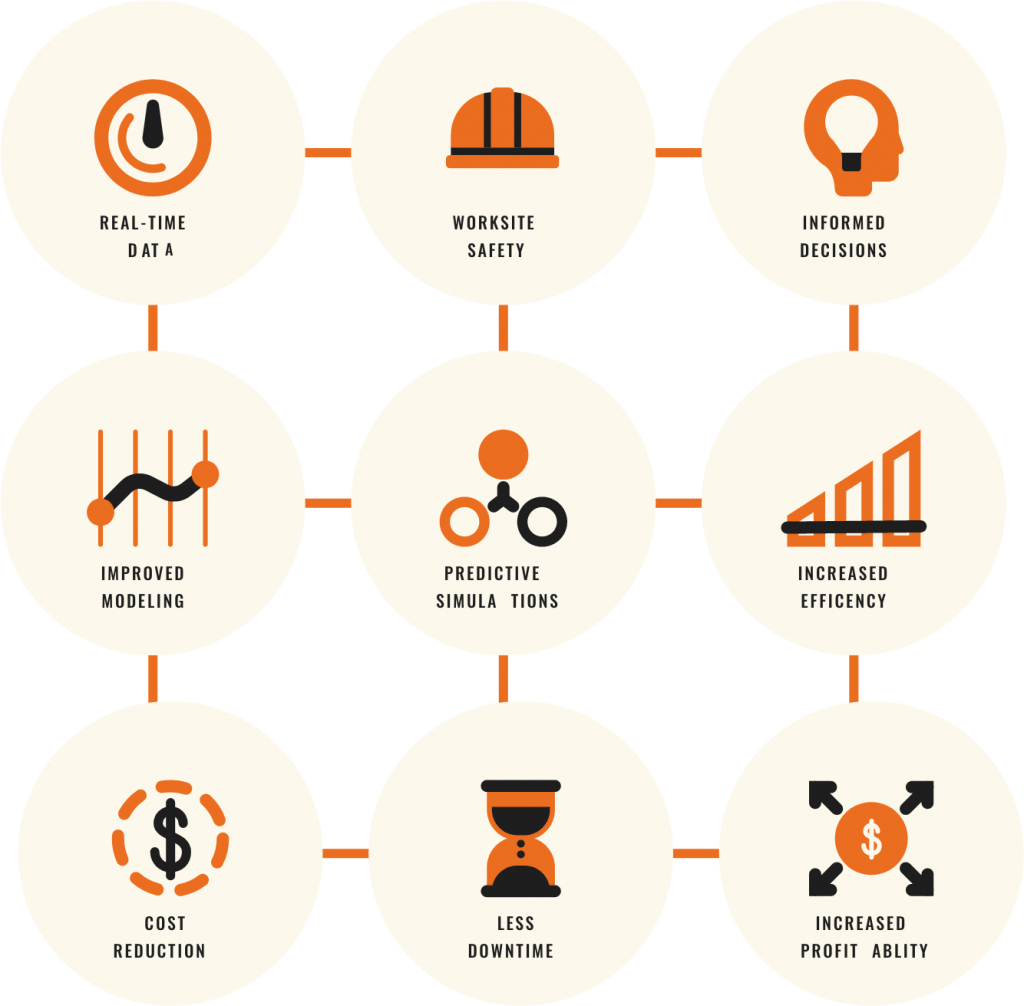

The OASys System Benefits your entire operation.